Week 1: Gearbox Concept

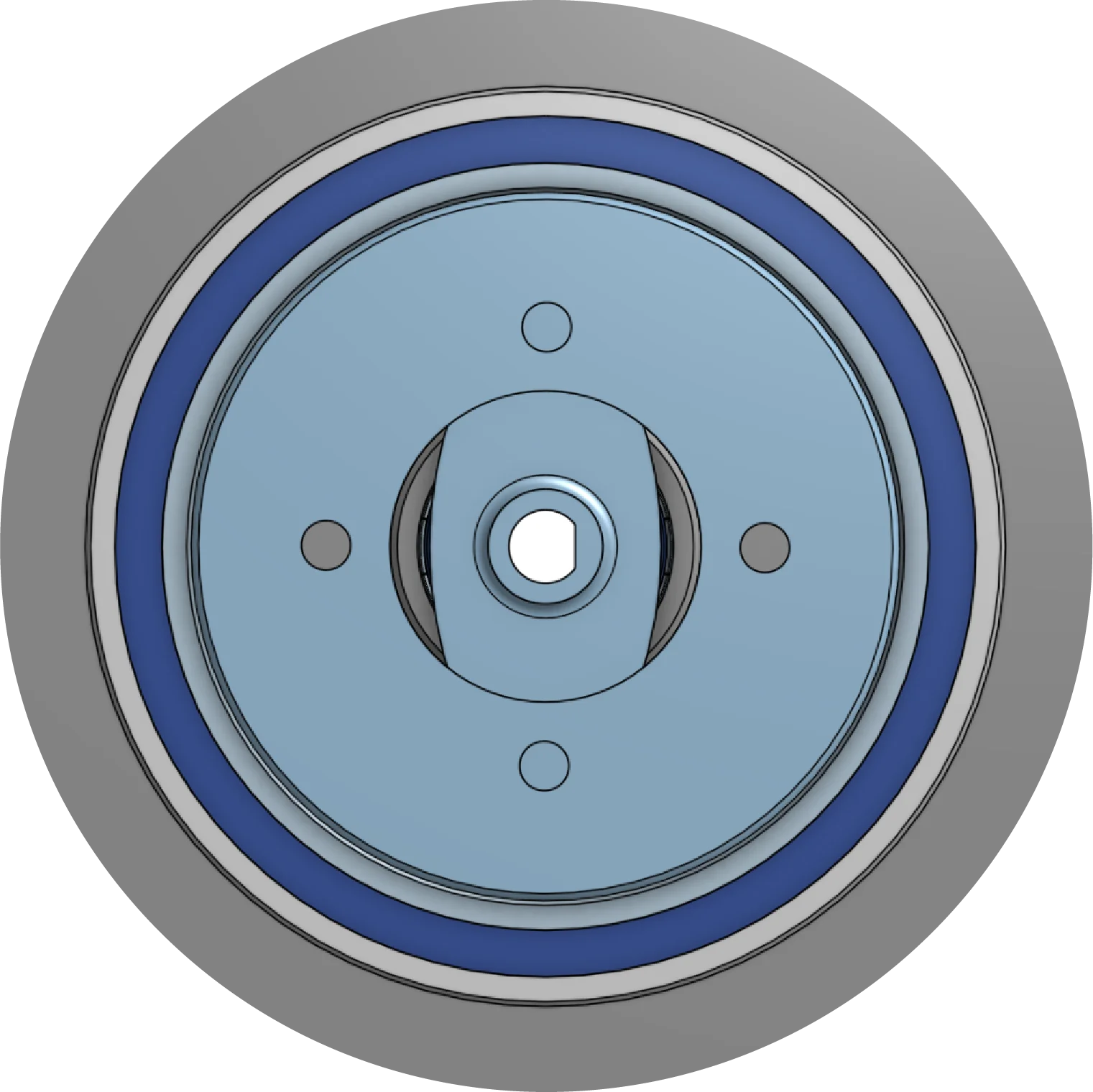

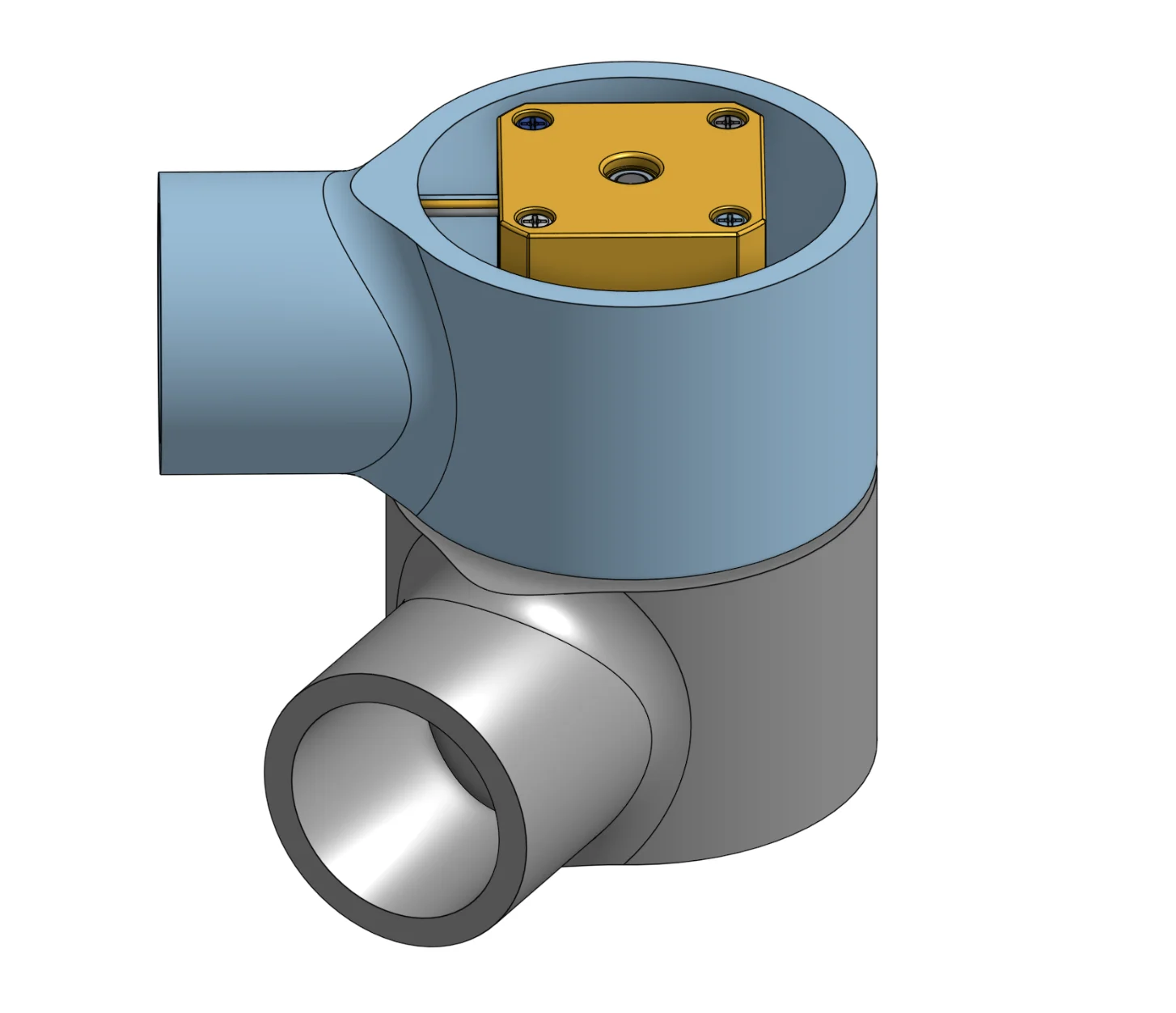

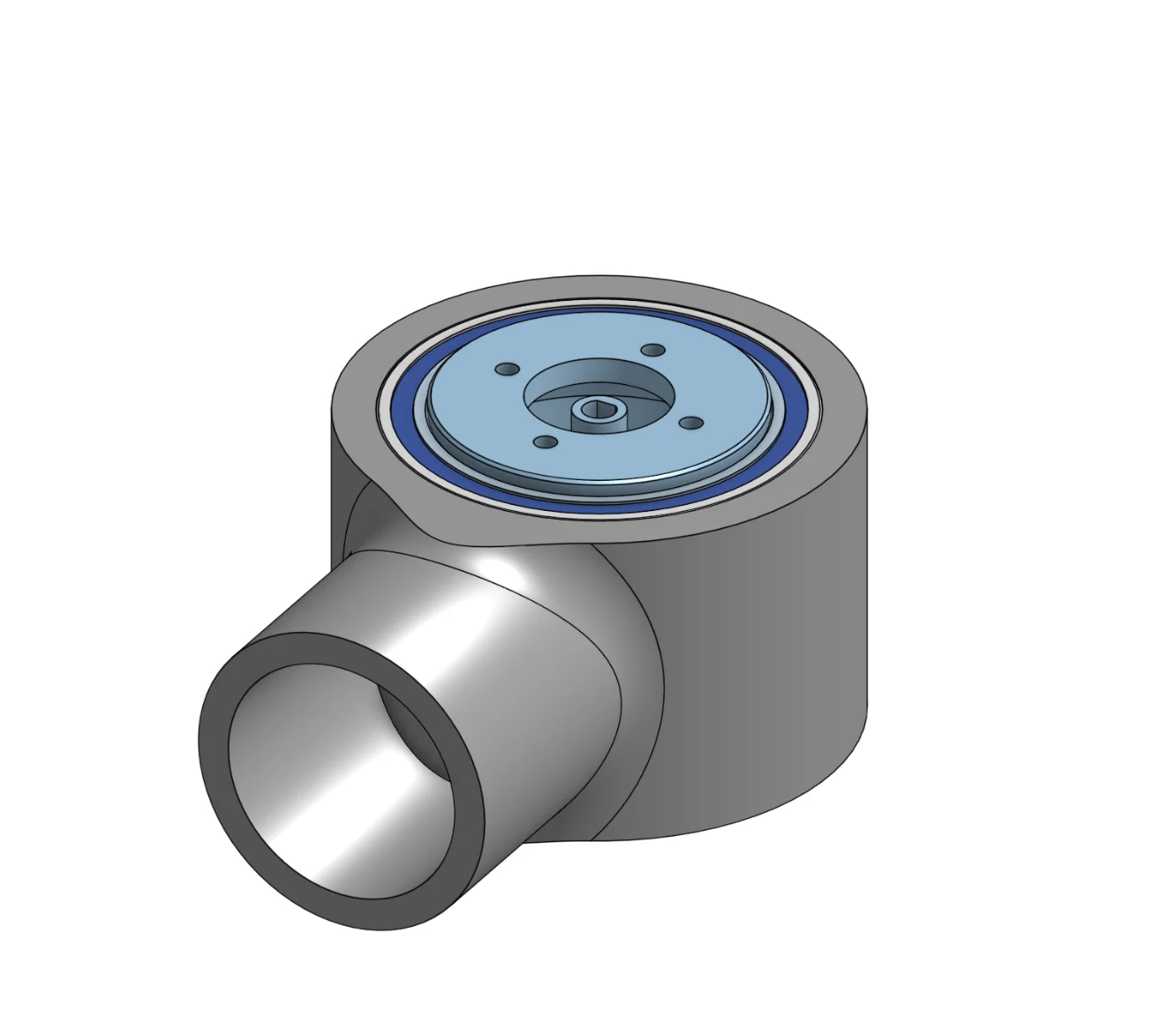

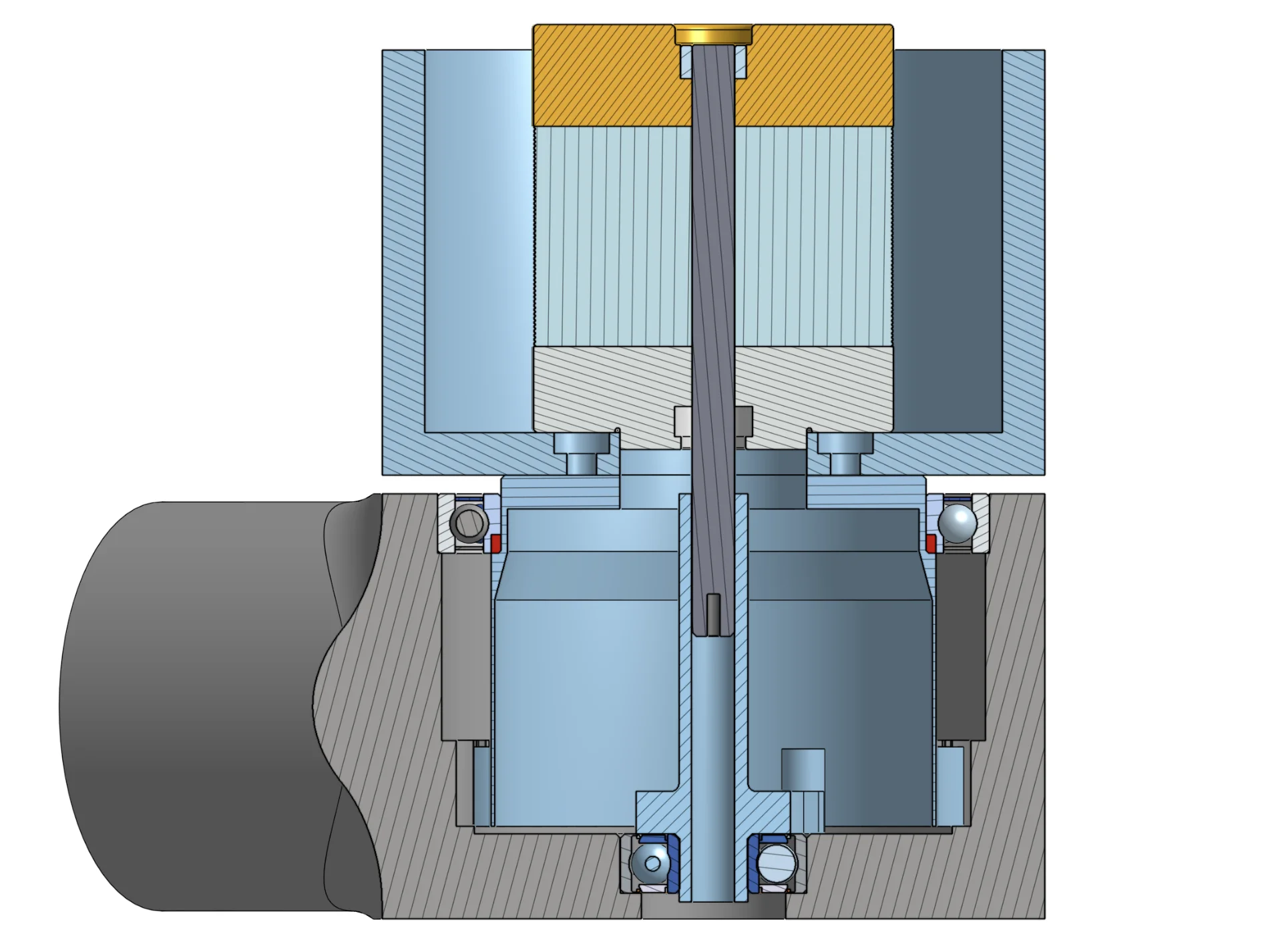

The idea for this project came about when I was working on a backdrivable high gear ratio hand crank fan for a class project where my team was designing 1-D electromechanical Flappy Bird. Shortly after prototyping a harmonic drive for the fan, I realized that it was quite an elegant design due to its low part count and therefore cost.